Want to extend the service life of rotating parts and oil?

Good lubrication is important for a long service life. Kinematic® series filter systems have been developed on the basis of many years of experience with filtration and service life extension of various types of oil.

Our Kinematic®series oilfiltration & oilcondtioning systems give you the option to greatly extend the service life of rotating parts and oil! Thanks to very clean and very dry oil you obtain considerably better lubrication. You get this benefit during the running hours of your drive as long as the Kinematic is connected.

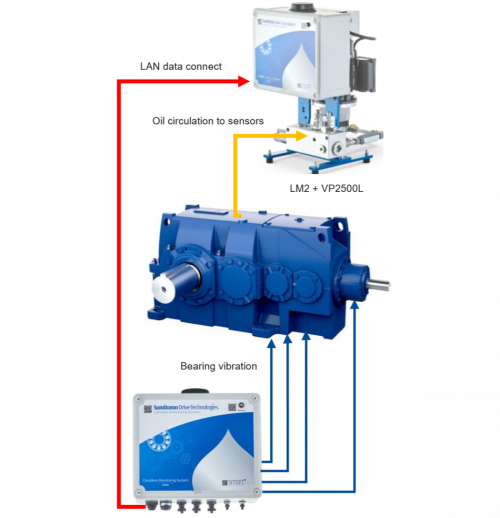

LM2 Gears - Remote Condition Monitoring System

- 24/7 monitoring of important drives by parameters such as water, oil temperature, viscosity and wear development. Optional vibrations can be connected.

- Data securely stored in the Cloud behind passwords. Overview of alarms - download periodic management reports.

- First sensor oil temperature & water saturation pre-installed

- Equipped with GPRS / GPS data SIM and LAN connection as standard.

- Two NO / NC contacts - Flowswitch monitoring and oil pressure or filter monitoring.

- QR codes on frontpanel for quick access to SSL web application or CMS help desk.

- The IP66 prtotected system cabinet - Suitable for indoor and outdoor applications

SMART monitoring concepts

Our LM2Gears series condition monitoring systems give you the opportunity to proactively monitor your critical drives by monitoring the oil 24/7. The complete ‘Entry-level’ model LM2 Gears is equipped with intelligent oil sensors. It will give you a timely warning by e-mail and SMS if a critical parameter is exceeded and your drive is at risk. Valuable measurement data can easily be managed by the internet application. The "Early-warning" method is one of the best. "React on facts and avoid damage!" The professional entry model LM2 Gears can also be connected to the entry model LM2 Vibration Extension Box. In this way, oil sensors and vibration sensors are easily combined into an advanced remote CMS starter package.

TIP! Choose the LM3 series CMS for in-depth analyses or diagnostics. The LM3 series CMS is also suitable for monitoring multiple drives in one room. Both CMS series LM2 & LM3 can be connected to SCADA or be part of a platform

LM2 Vibrations E . B . Remote Monitoring System

- 24/7 monitoring of important drives by vibration parameters easily connected on a LM2 Gears

- For the reliable vibration monitoring of bearings in machines and equipment. #

- Condition-based maintenance thanks to monitoring of unbalance, rolling element bearing or gear state

- Inputs for the simultaneous detection of up to four vibration sensors

- Two switching outputs for pre-alarm and main alarm

- Analogue inputs for monitoring further measurement variables

SMART monitoring concepts

Our LM2Vibration series condition monitoring systems give you the opportunity to proactively monitor your critical drives by monitoring the vibrations 24/7. This complete ‘Entry-level’ model LM2 Vibrations EB [Extension Box] is equipped with intelligent vibration electronics by IFM®. Connected to a LM2Gears CMS it will give you a timely warning by email and SMS if a critical parameter is exceeded and your drive is at risk.

Valuable measurement data can easily be managed by the internet application. The professional entry model LM2 Vibration EB has to be connected to the entry model LM2 Gears CMS. In this way, oil sensors and vibration sensors are easily combined into an complte and advanced remote CMS starter package.

TIP! Choose the LM3 series CMS for in-depth analyses or diagnostics. The LM3 series CMS is also suitable for monitoring multiple drives in one room.

TIP! Both CMS series LM2 & LM3 can be connected to SCADA or be part of a platform that can be managed independently and worldwide.

Remote